- In Line

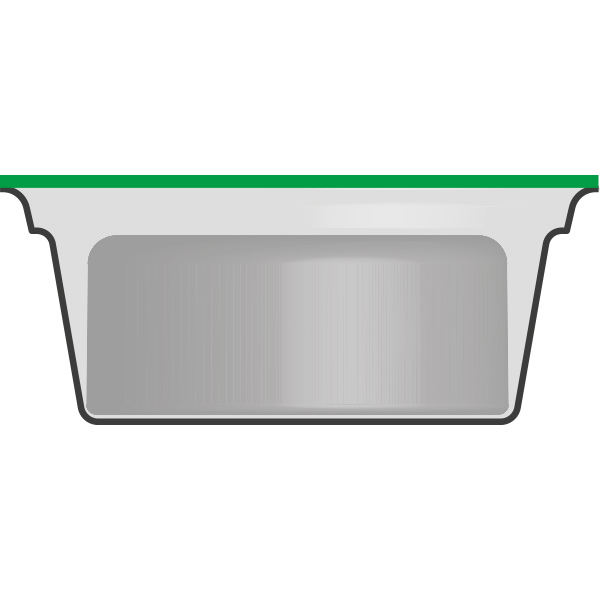

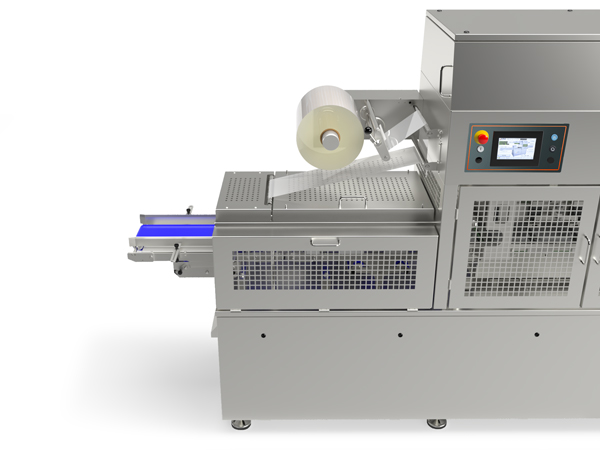

FoodPack 1485

FoodPack 1485 is a fully automatic traysealer for large-scale production. Equipped with a large sealing area, it seamlessly integrates into any production line. With CPS technology, it reaches maximum production potential. Configurable for various packaging applications like fruit, meat, ready meals, and fish.

-

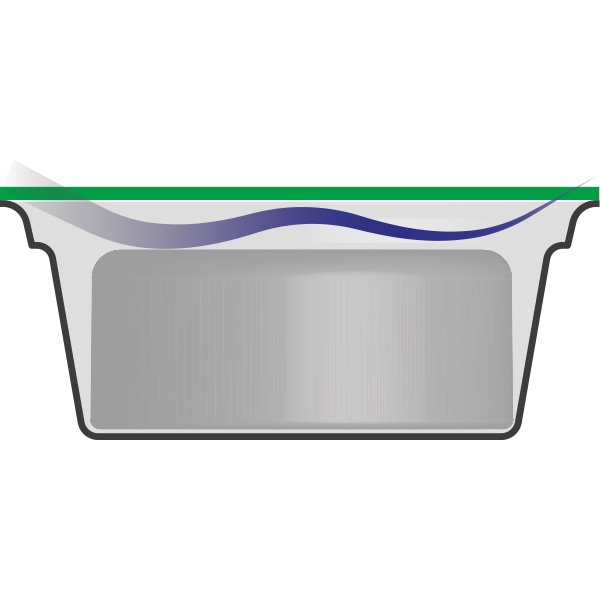

Sealing

Sealing

-

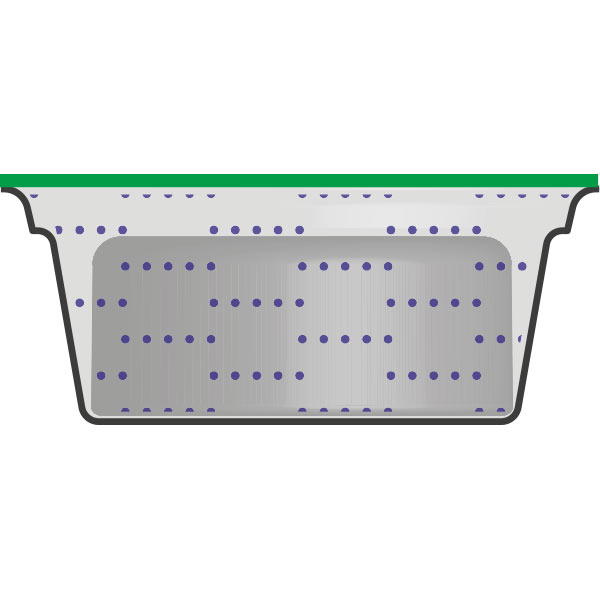

Gas Flush

Gas Flush

-

MAP/ATP

MAP/ATP

-

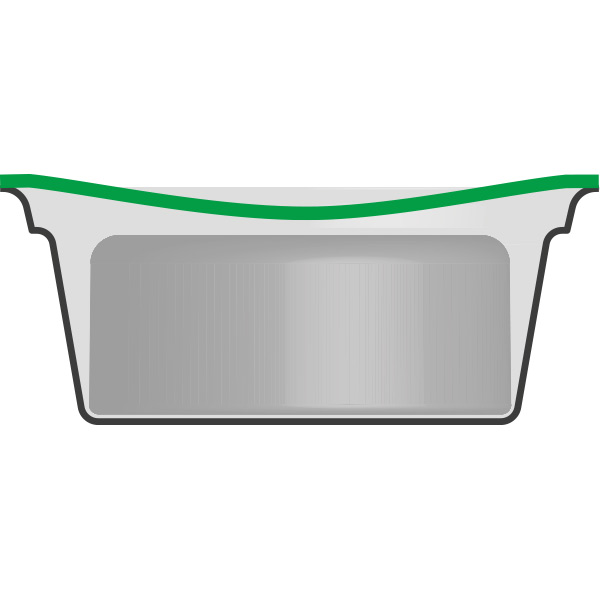

Vacuum

Vacuum

-

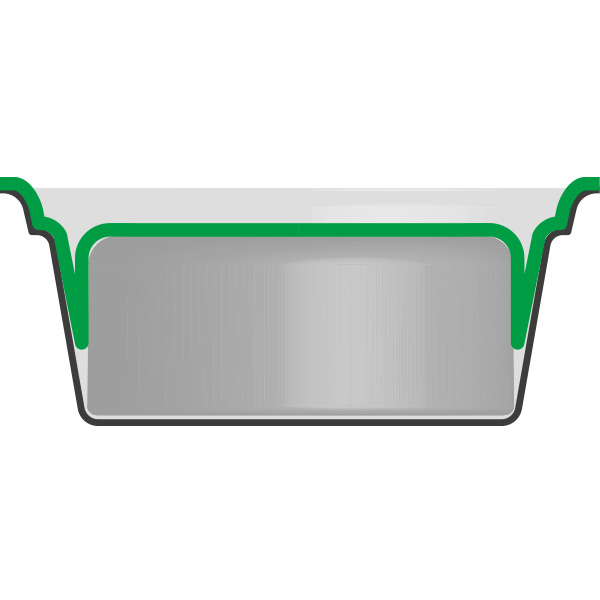

Skin

Skin

-

Overskin

Overskin

-

Extraskin

Extraskin

-

Extraskin on Cardboard

Extraskin on Cardboard

| Technical Data | FoodPack 1485 | ||

| Dimensions | 375 x 90 x h 196 cm | ||

| Weight | approx. 1400 Kg | ||

| Air Consumption | 6 bar - 5 Nlt/cycle | ||

| Sealing Area | 850 x 350 x h 120 mm |

CPS technology

The machine features seamless tray inflow technology, where the conveyor belt effortlessly separates and transports trays without any interruptions, all the way into the sealing mold. This is made possible through the electronic interpolation of jaws with the conveyor belts.

Anti-crush system

The photocell indicates whether a tray is not properly positioned, triggering an alarm that halts the sealing process and avoids potential damage to the tray.

OPTIONAL: Film pre-heating system for Skin

The Pre-Heating System optimizes packaging time by heating the film from the moment you choose skin packaging, streamlining the work process for greater efficiency.

Easy belt disassembly

This enables efficient sanitization of all components at the machine’s inlet and outlet within a short timeframe.

TECHNOLOGIES

| E-MEC TECHNOLOGY Based on the fully electromechanical movement of the working station, this technology enables higher speed and productivity. |

| PROGAS SYSTEM Technology patented by ILPRA that guarantees a lower use of gas and a higher working speed. Available on all models in this line |

| CONSTANT PLACEMENT SYSTEM Cutting-edge technology that enables a constant inflow of trays. The interpolation of the belts and jaws increases the production speed. |

| Optional: ID CONTROL SYSTEM Recognition of authorised personnel by badge. Up to three levels of identification. |

| Optional: EXTRASKIN SYSTEM It allows Skin packaging even at high degrees of protrusion. |

| Optional: PRE-HEATING SYSTEM Pre-heating of the film to optimize packaging in Skin. |

| Optional: PREDICTIVE Predictive maintenance system that enables the planning of the overhaul and replacement of components. |

| Optional: ANTI-CRUSH SYSTEM The machine checks the correct positioning of the trays, stopping sealing in the event of incorrect positioning. |