- Seal Box

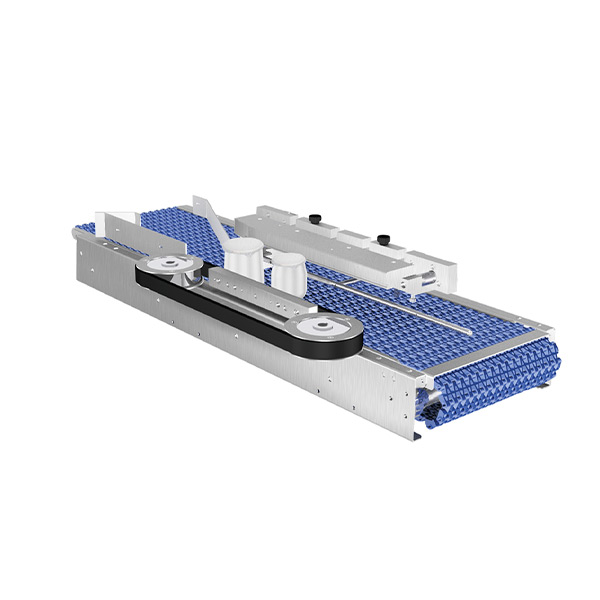

Seal Box 300 e 400

The Seal Box line boasts models that cater specifically to the packaging of non-stackable containers, particularly small bottles and jars. The machines are versatile in that they offer an optional dosing system, which can be integrated within the machine or externally. These models of Seal Box are popularly chosen by those who require cost-effective and efficient packaging solutions for cosmetic and food products. With a Seal Box machine, you can be rest assured that your products will be packaged with precision and care, ensuring that they remain fresh and in good condition for the end consumer.

-

- Sealing -

- Sealing -

| Technical data | Seal Box 300 | Seal Box 400 | |

| Dimensions | 191 x 162 x h 232 cm | 191 x 162 x h 232 cm | |

| Weight | circa 1000 Kg | circa 1000 Kg | |

| Electric Power Film | 6 kW | 7 kW | |

| Pots per cycle | In accordance with format and product | In accordance with format and product | |

| Ø Max Cups Film | 300 mm | 400 mm | |

| Max height Cup | 220 mm | 220 mm |

Touch Screen Panel

Rotary table

Fully washable

Optional: external doser

ACCESSORIES

| PICK & PLACE Device that allows the automatic placing of pre-filled containers inside the machine. |

| ULTRA CLEANING SYSTEM Each of our models can be equipped with sanitization systems such as UVC lamps, pulsed light and hydrogen peroxide. |

| DOSING SYSTEMS Volumetric, timed, drawer, flowmeter: ILPRA has every type of doser to make your filling fast and accurate. |

| CRIMPING SYSTEM The crimping system is installed on the exit belt of glass or ceramic pot fillers. This allows the lid to be crimped to the side edge of the pot. |

| INKJET Inkjet printer that allows to complete your packaging with additional information such as: expiration date, production lot, etc. |