- Automatics

FoodPack Speedy +

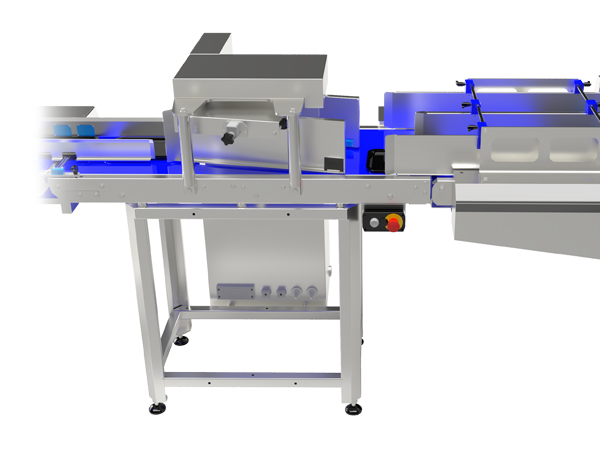

Introducing Speedy +, an inline traysealer that seamlessly integrates into any production line, enhancing performance. This automatic packaging machine, with a double chain transport system, surpasses the FoodPack Speedy PN20 model in both efficiency and precision. Ideal for those seeking automated solutions on a budget.

-

Sealing

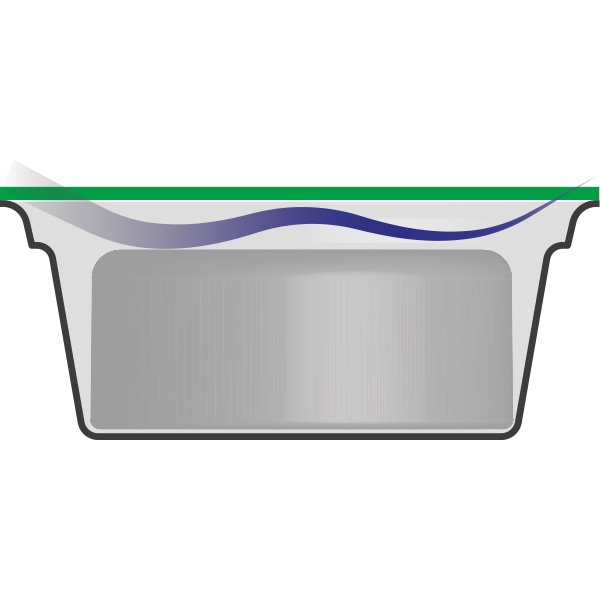

Sealing

-

Gas Flush

Gas Flush

-

MAP/ATP

MAP/ATP

-

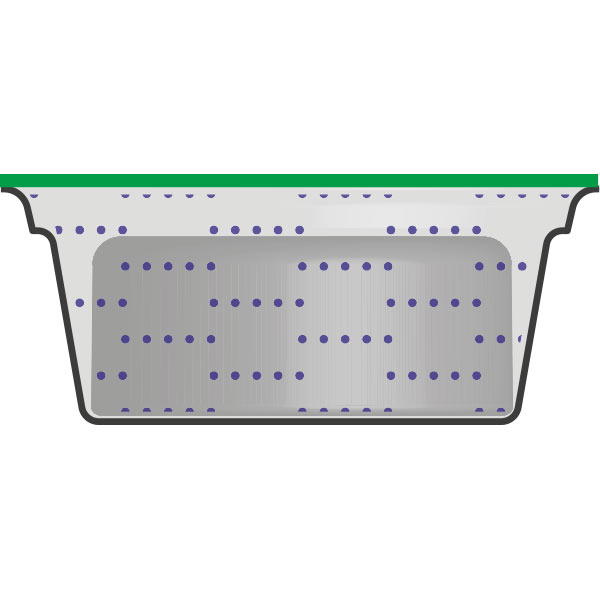

Vacuum

Vacuum

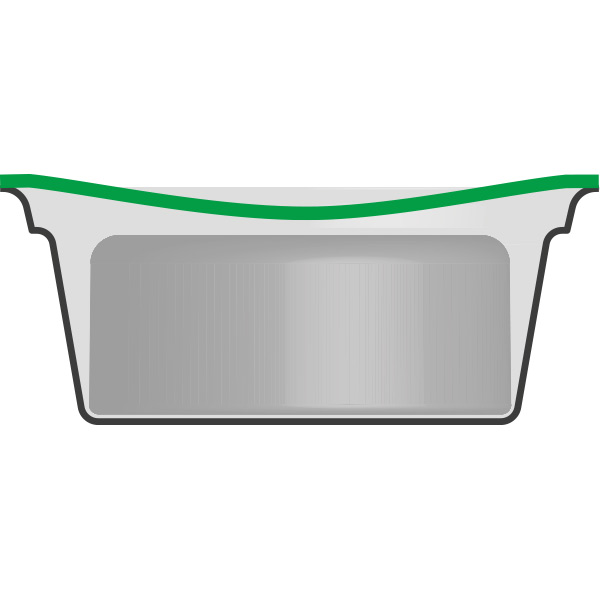

-

Skin

Skin

-

Overskin

Overskin

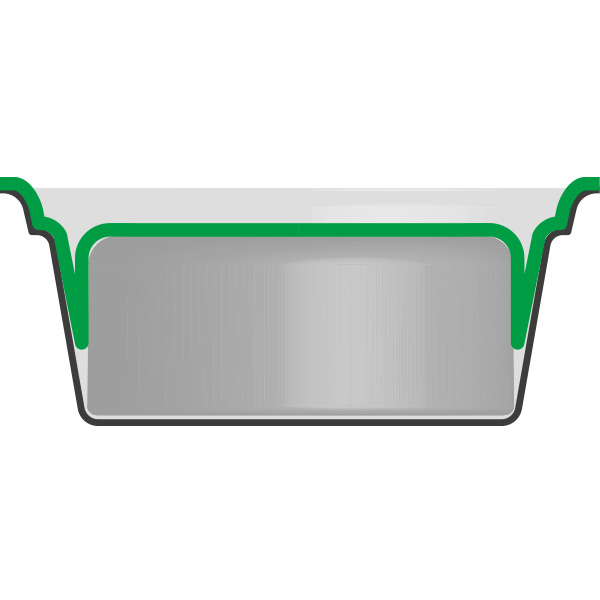

-

Extraskin

Extraskin

-

Extraskin on Cardboard

Extraskin on Cardboard

| Technical Data | FoodPack Speedy + | ||

| Dimensions | 287 x 106 x h 158 cm | ||

| Weight | 600 (N) / 680 (VG) Kg | ||

| Air consumption | 6 bar - 35 (N) / 40 (VG) Nlt/cycle | ||

| Sealing area | 380 x 270 x h 135 mm |

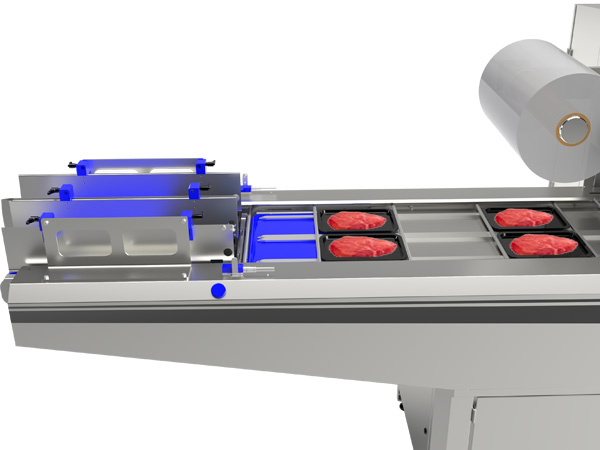

Double chain with rods

Speedy+ enables in-line work and boasts enhanced tray transport using a double chain with rods. With synchronized and interpolated movement, high speeds are achieved while ensuring precise container positioning and gentle handling.

Touch Screen Panel

The unit controls all machine parameters and stores quick-use recipes. The panel includes access to the self-diagnostic system for problem-solving.

Diverger for trays

Optionally, equip it with the diverger model to effortlessly switch between single and double production lines.

Unwinding-rewinding system with automatic reels

This unit automatically places heat-sealing film, unwound from a reel, in the sealing area and rewinds the scraps after the sealing-cutting operation.

TECHNOLOGIES

| PROGAS SYSTEM Technology patented by ILPRA that guarantees a lower use of gas and a higher working speed. |

| E-MEC TECHNOLOGY Based on the fully electromechanical movement of the working station, this technology enables higher speed and productivity. |

| Optional: EXTRASKIN SYSTEM It allows Skin packing even at high degrees of protrusion. |

| Optional: PRE-HEATING SYSTEM Pre-heating of the film to optimize packaging in Skin. |