- Automatics

FoodPack Speedy

ILPRA’s FoodPack Speedy is the ideal tray sealing machine for those seeking a fast and precise work cycle. With its efficiency, flexibility, durability, and cost-effectiveness, it offers numerous accessible applications, including simple sealing, vacuum sealing, MAP, and various types of Skin packaging. The user-friendly color touch screen interface ensures ease of use, even for inexperienced personnel. Benefit from the reliability of FoodPack Speedy, a trusted choice evidenced by the hundreds of units ILPRA sells worldwide each year.

-

Sealing

Sealing

-

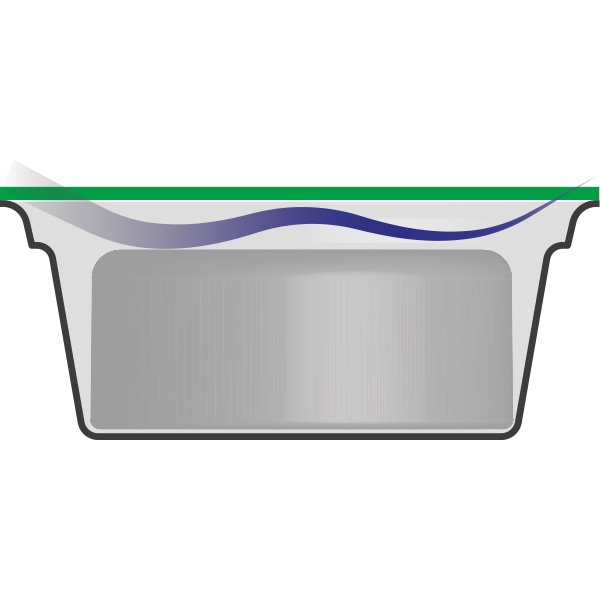

Gas Flush

Gas Flush

-

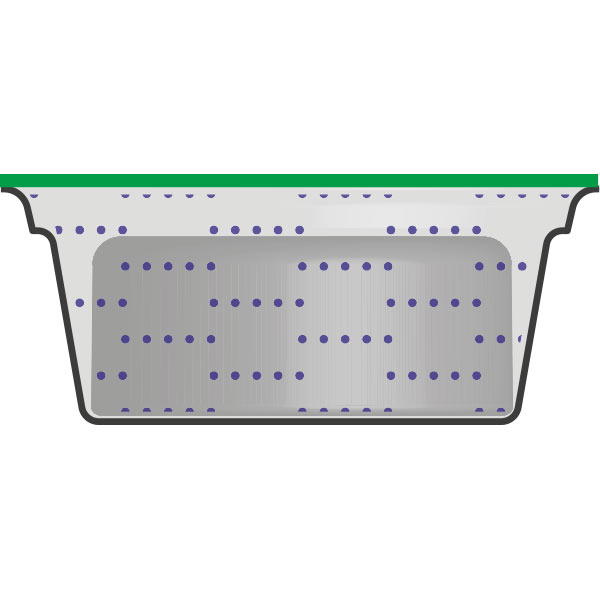

MAP/ATP

MAP/ATP

-

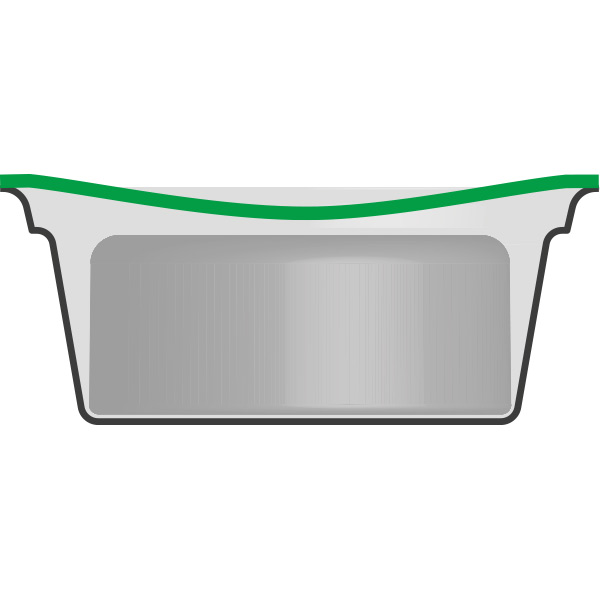

Vacuum

Vacuum

-

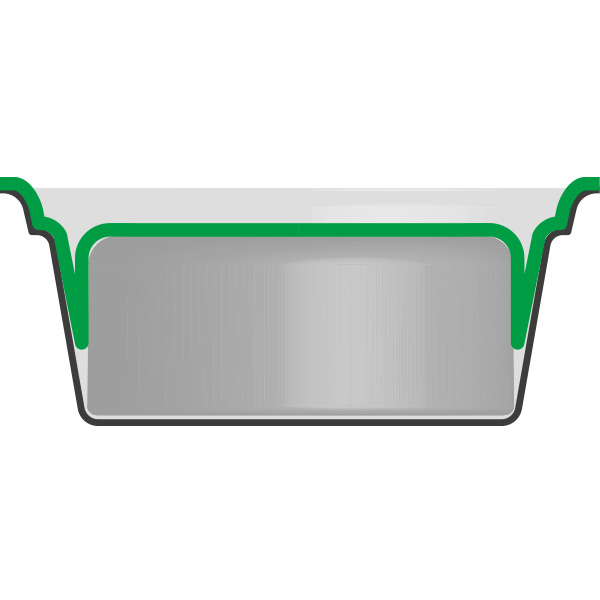

Skin

Skin

-

Overskin

Overskin

-

Extraskin

Extraskin

-

Extraskin on Cardboard

Extraskin on Cardboard

| Technical Data | FoodPack Speedy | ||

| Dimensions | 285 x 106 x h 158 cm | ||

| Weight | approx. 620 (N) / 650 (VG) Kg | ||

| Air consumption | 6 bar - 35 (N) / 40 (VG) Nlt/cycle | ||

| Sealing area | 380 x 270 x h 135 mm |

Large Loading Area

The servo motor-activated panel enables adjustable speed, acceleration, and deceleration. Additional tracks can be included to transport more trays per cycle.

Touch Screen Panel

This unit controls all machine parameters and stores recipes for quick access by the operator. The panel also provides access to the self-diagnostic system to address any machine issues.

Quick mould change

Quick and easy mould changing, either manually or with a special trolley, enables seamless transitions between different moulds.

Unwinding-rewinding system with automatic reels

Automatic heat-sealing film placement, unwinding from a reel, sealing the area, and rewinding scraps.

TECHNOLOGIES

| PROGAS SYSTEM Technology patented by ILPRA that guarantees a lower use of gas and a higher working speed. |

| E-MEC TECHNOLOGY Based on the fully electromechanical movement of the working station, this technology enables higher speed and productivity. |

| Optional: EXTRASKIN SYSTEM It allows Skin packing even at high degrees of protrusion. |

| Optional: PRE-HEATING SYSTEM Pre-heating of the film to optimize packaging in Skin. |