- Semi-automatics

FoodPack 400 Extra

The 400 Extra is a compact semi-automatic tray sealer, ideal for small production environments. It is designed specifically for skin food packaging, allowing small businesses to achieve quality packaging with a low investment. This ILPRA product, along with its rotary version, is capable of processing skin packaging at high levels of protrusion (up to 60 mm).

-

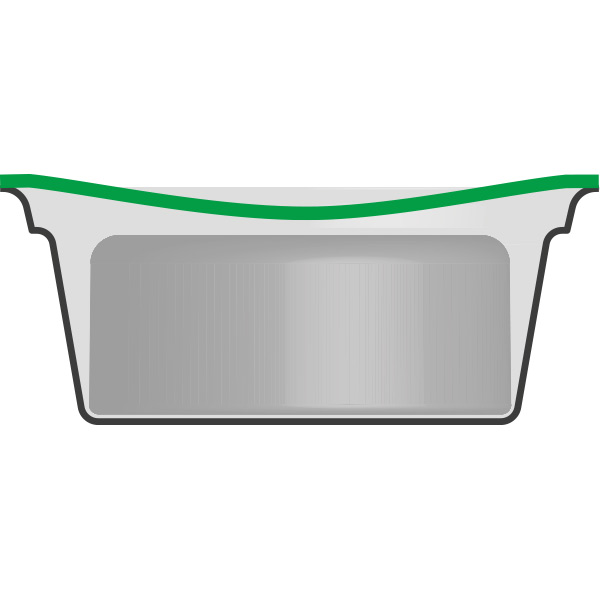

Sealing

Sealing

-

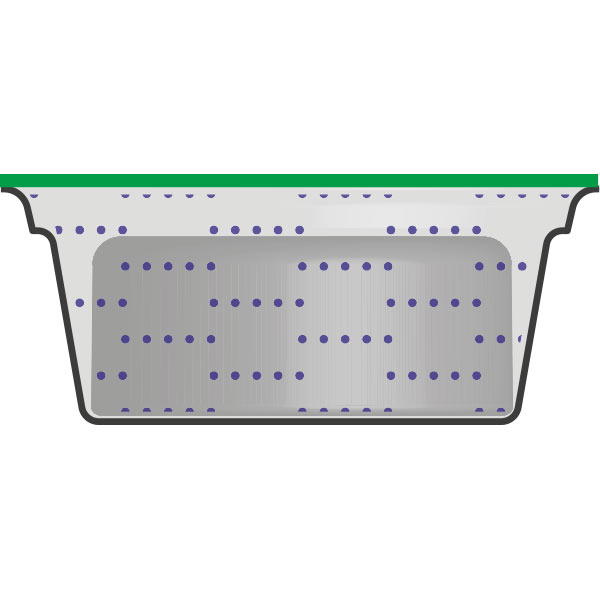

Gas Flush

Gas Flush

-

MAP/ATP

MAP/ATP

-

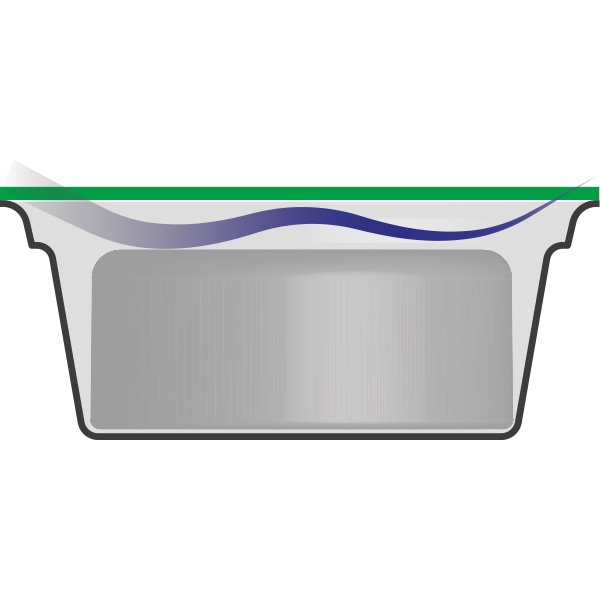

Vacuum

Vacuum

-

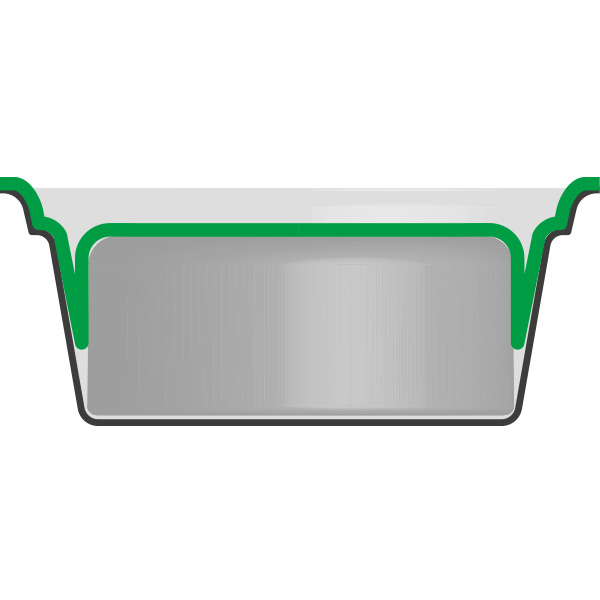

Skin

Skin

-

Overskin

Overskin

-

Extraskin

Extraskin

-

Extraskin on Cardboard

Extraskin on Cardboard

| Technical Data | FoodPack 400 Extra | ||

| Dimensions | 105 x 108 x h 155 cm | ||

| Weight | approx. 400 Kg | ||

| Air Consumption Vacuum Gas | 6 bar - 35 Nlt/cycle | ||

| ExtraSkin Air Consumption | 6 bar - 80 Nlt/cycle | ||

| Vacuum Gas Sealing Area | 420 x 300 x h 135 mm | ||

| ExtraSkin Sealing Area | 400 x 300 x protrusion 50 mm (optional 70 mm) |

Touch Screen Panel

The touch screen control panel allows easy configuration of all working parameters. Furthermore, multiple recipes can be stored for quick operator access.

Up to six different types of packaging

Sealing only

MAP

Vacuum

Skin on cardboard

Skin on plastic plate

Skin on tray

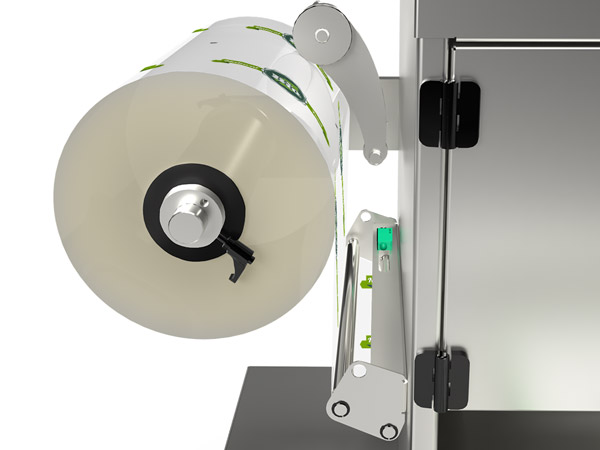

Automatic unwinder and rewinder

This system automatically unwinds the heat-sealing film, seals and cuts it, and rewinds the scraps. It is mechanically operated and can be equipped with a “centered print” system for aligning the film with the tray. It supports both printed and neutral film.

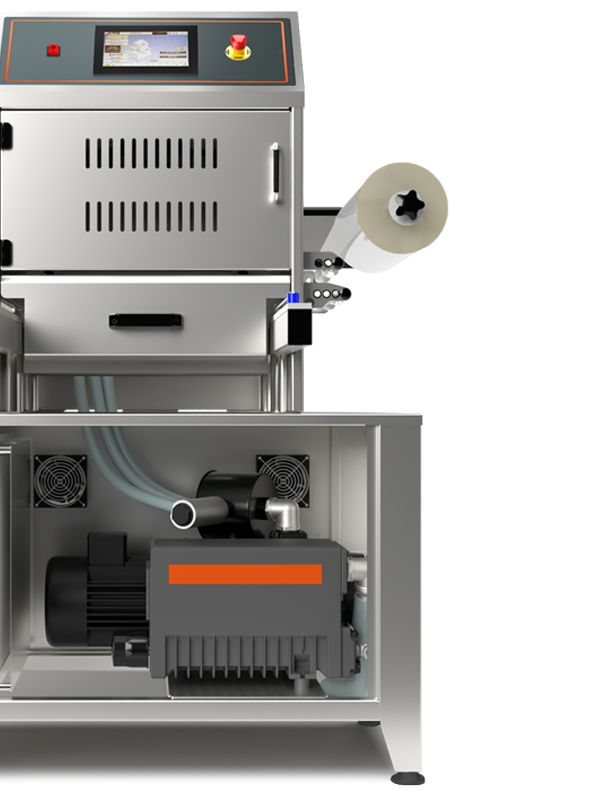

Vacuum pump in the machine

This model includes the 300m3 vacuum pump internally to ensure a compact and space-saving design in your production environment.

TECHNOLOGIES

| PROGAS SYSTEM Technology patented by ILPRA that guarantees a lower use of gas and a higher working speed. |

| EXTRASKIN It allows Skin packing even at high degrees of protrusion. |