- Semi-automatics

FoodPack 400

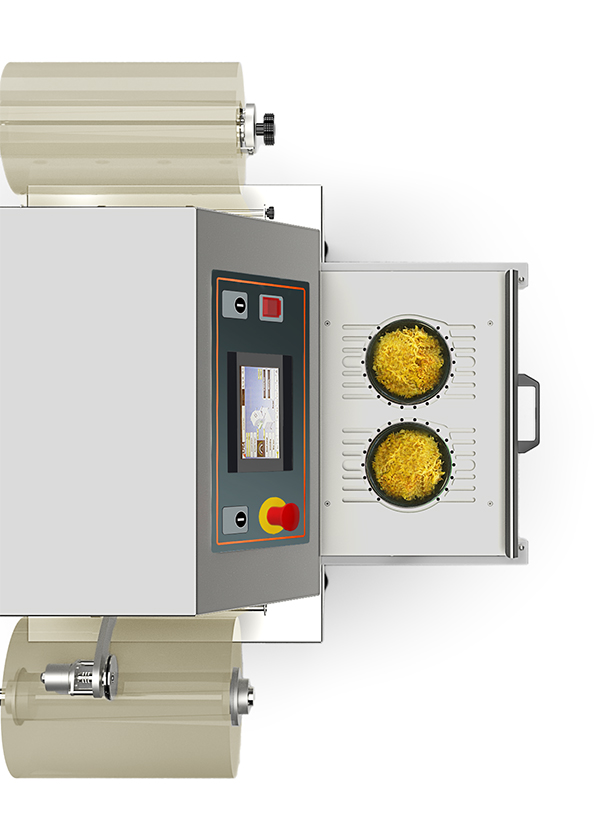

The FoodPack 400 tray sealer is ideal for sealing various tray types (plastic, aluminum, laminated cardboard) with a spacious sealing area. Packaging is effortless and user-friendly: trays are inserted and extracted manually, while film unwinding/rewinding is automated.

-

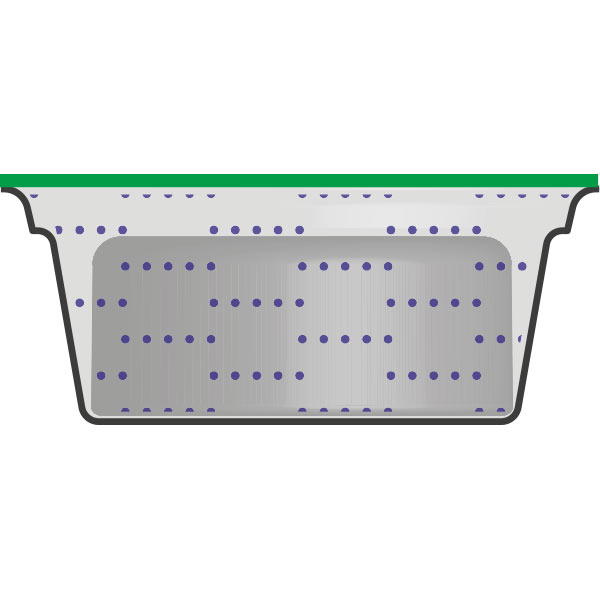

Sealing

Sealing

-

MAP/ATP

MAP/ATP

-

Vacuum

Vacuum

-

Skin

Skin

-

Overskin

Overskin

| Technical Data | FoodPack 400 | ||

| Dimensions | 106 x 102 x h 143 cm | ||

| Weight | approx. 180 (N) - 300 (VG) Kg | ||

| Air consumption | 6 bar - 20 Nlt/cycle | ||

| Sealing area | 400 x 285 x h 135 mm |

Touch Screen Panel

Working parameters can be set through the touch screen control panel. Plus, multiple recipes can be stored for quick access by the operator.

Large sealing area

FoodPack 400 offers a spacious sealing area for increased production volume and versatile mould configuration.

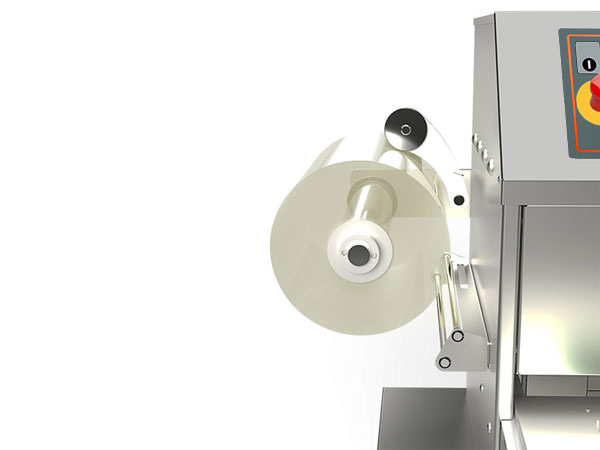

Electronic unwinder and rewinder

The system automatically unwinds the heat-sealing film, seals and cuts it, and rewinds the scraps. It can be electronically operated and optionally equipped with a “centered print” system for precise tray alignment. It supports both printed and neutral film.

Quick Mould Change

Quickly change the size without tools by easily removing the mould.

| PROGAS SYSTEM Technology patented by ILPRA that guarantees a lower use of gas and a higher working speed. |