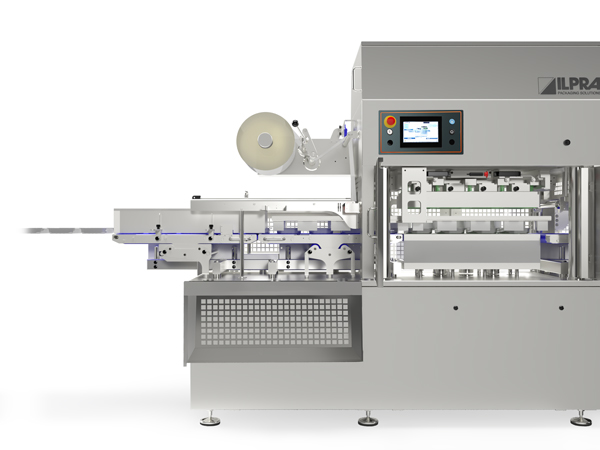

- In Line

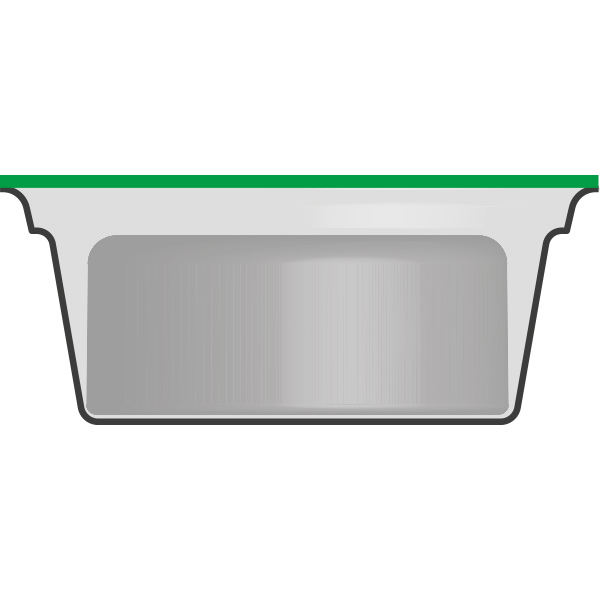

FoodPack 1450

Food Pack 1450 is a versatile, high-performance in-line machine designed to meet market demands: with the capacity to handle three 187×137 mm containers concurrently, this fully electronic model combines reliability and efficiency. It can be configured for various packaging applications including fruit, meat, ready meals, and fish.

-

Sealing

Sealing

-

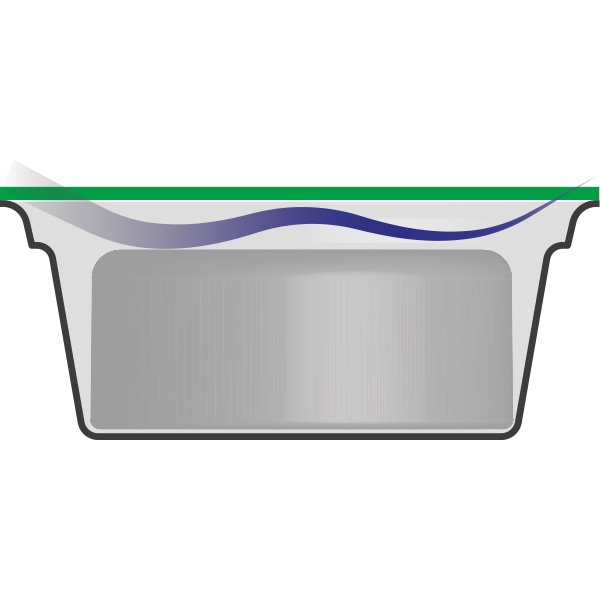

Gas Flush

Gas Flush

-

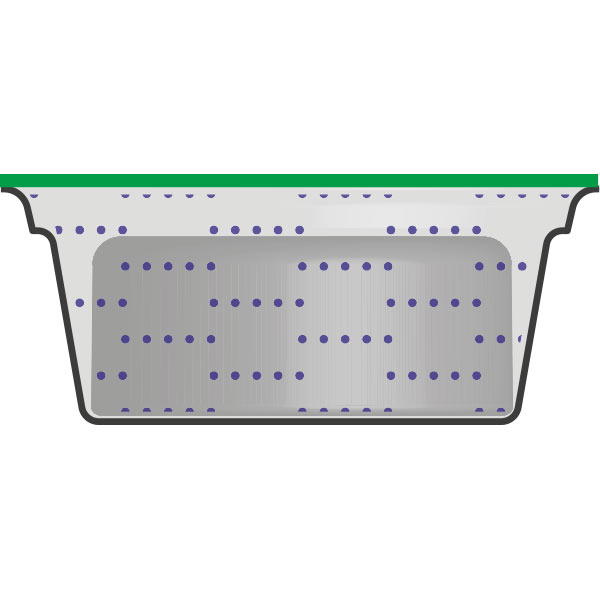

MAP/ATP

MAP/ATP

-

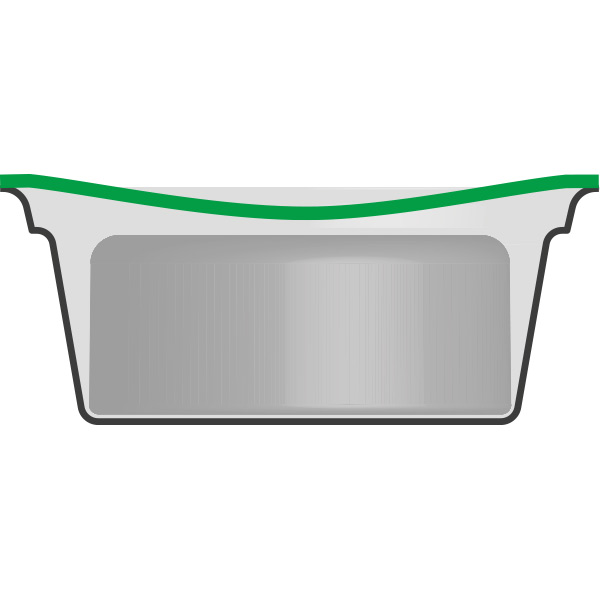

Vacuum

Vacuum

-

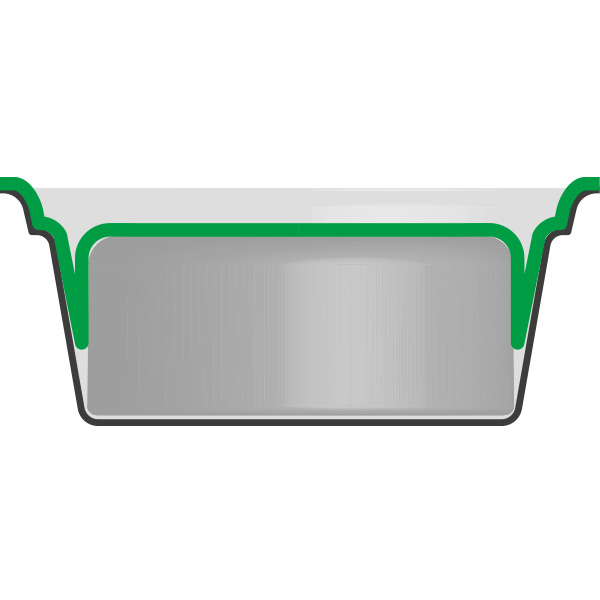

Skin

Skin

-

Overskin

Overskin

| Technical Data | FoodPack 1450 | ||

| Dimensions | 331 x 90 x h 190 cm | ||

| Weight | approx 1100 Kg | ||

| Air Consumption | 6 bar - 5 Nlt/cycle | ||

| Sealing Area | 560 x 350 x h 120 mm |

CPS Technology

Continuous tray inflow technology; conveyor belt separates and transports trays without stopping, electronically interpolating jaws with the belts.

Constant torque servo drive motors

The unwinder/rewinder system relies on two brushless motors: one for unwinding and the other for maintaining appropriate film tension. These features enable precise control of movement parameters and unwinding of both neutral and printed film.

Anti-crush system

The photocell detects tray misplacement, triggering an alarm to halt the sealing operation and prevent crushing.

Automatic unwinding system

The unit automatically positions the required amount of heat-sealing film, handles rewinding scraps, and maintains correct tension during operation. It features electronic drive, special sensors for tension control, and pneumatic expansion for quick and effortless loading/unloading.

TECHNOLOGIES

| E-MEC TECHNOLOGY Based on the fully electromechanical movement of the working station, this technology enables higher speed and productivity. |

| PROGAS SYSTEM Technology patented by ILPRA that guarantees a lower use of gas and a higher working speed. |

| Optional: PRE-HEATING SYSTEM Pre-heating of the film to optimize packaging in Skin. |