- In Line

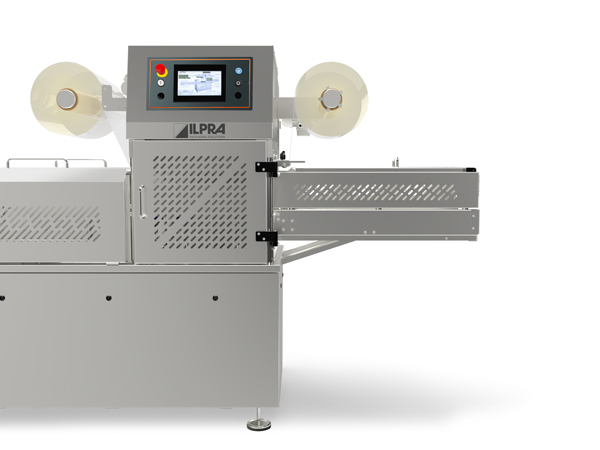

FoodPack 1440

FoodPack 1440 is an ultra-compact and easy-to-integrate solution for in-line tray sealing. It’s perfect for packaging ready meals, pasta, sliced meats, and more.

-

Sealing

Sealing

-

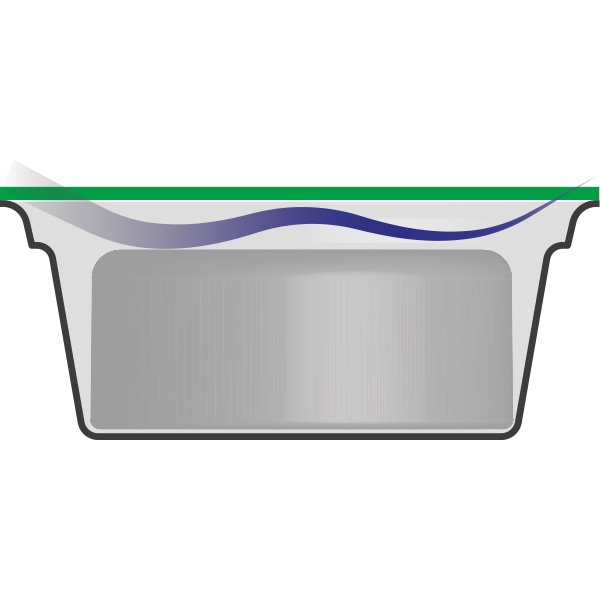

Gas Flush

Gas Flush

-

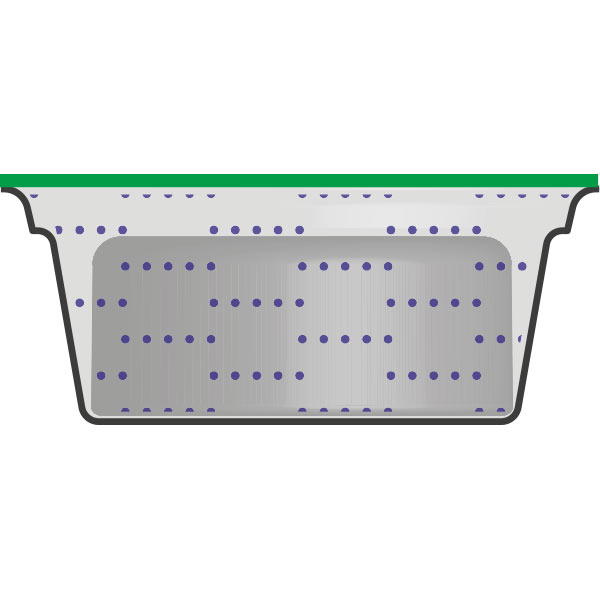

MAP/ATP

MAP/ATP

-

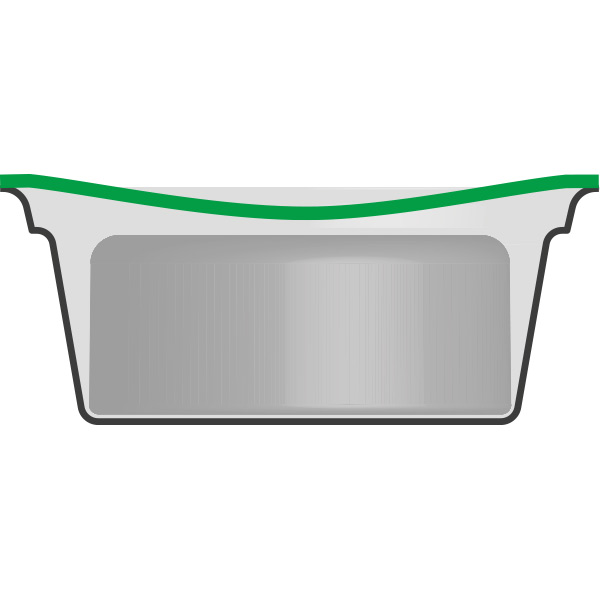

Vacuum

Vacuum

-

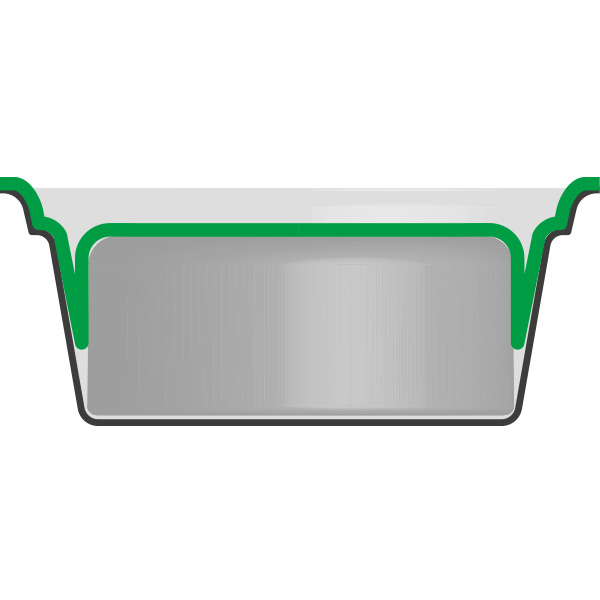

Skin

Skin

-

Overskin

Overskin

| Technical Data | FoodPack 1440 | ||

| Dimensions | 309 x 105 x h 154 cm | ||

| Weight | approx. 1000 Kg | ||

| Air Consumption | 6 - 5 (N) / 7 (VG) Nlt/Cycle | ||

| Sealing Area | 400 x 270 x h 120 mm |

Compact, chain and walking beam version

ILPRA provides various types of feed within the sealing area, including motorised tapes, walking beam, and chain. Each configuration has unique features in terms of versatility, speed, and use.

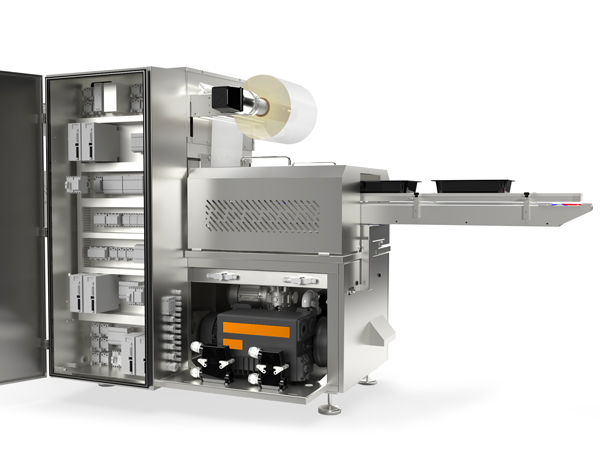

Total accessibility

This model is easily accessible to personnel, simplifying the cleaning process.

Servo activated jaws

The sealing area trays are handled by jaws, which are electronically controlled by an inverter. This allows for easy management of parameters to handle various products, from soup to fresh meat.

Unwinding-rewinding system with automatic reels

This unit automatically positions the heat-sealing film, unwinds it from a reel, seals, and rewinds the scraps. The system is electronically driven and controlled by a special sensor that maintains tension as variables change. Both unwinding and rewinding shafts have a pneumatic expansion system for optimal clamping and easy loading and unloading.

TECHNOLOGIES

| E-MEC TECHNOLOGY Based on the fully electromechanical movement of the working station, this technology enables higher speed and productivity. |

| PROGAS SYSTEM Technology patented by ILPRA that guarantees a lower use of gas and a higher working speed. |

| Optional: PRE-HEATING SYSTEM Pre-heating of the film to optimize packaging in Skin. |