- In Line

Fill Seal In Line

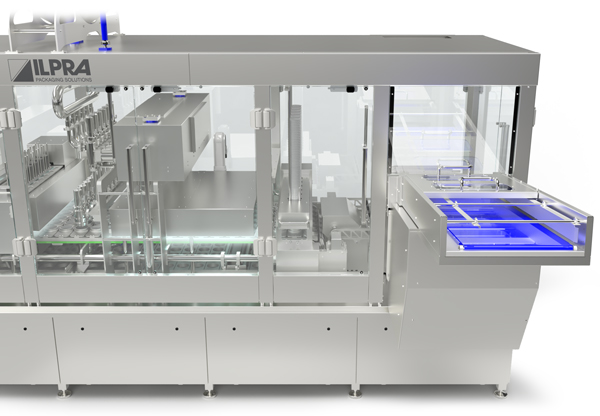

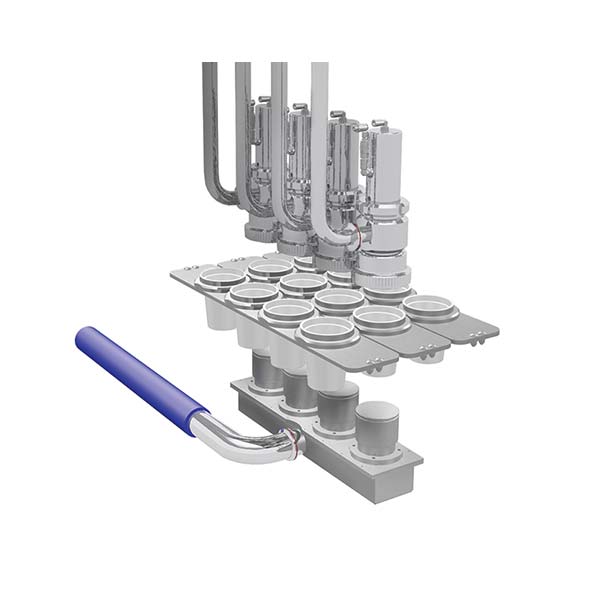

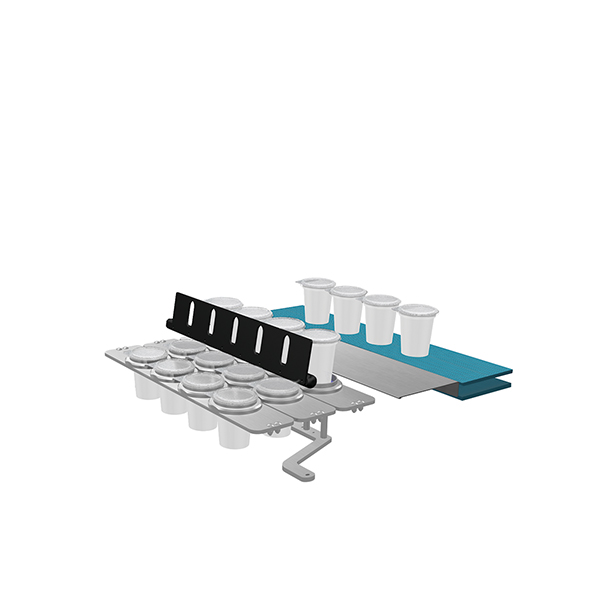

Our portfolio of in-line Fill Seal machines is ILPRA’s response to the need for large-scale manufacturing. The configuration of these machines is tailor-made depending on specific demands, e.g. type of packaging, production environment, hourly output, etc. The modular design enables a variety of accessories to be set up across the entire length of the machine. This configuration is perfect for customers needing to match production and sanitisation.

-

- MAP/ATP -

- MAP/ATP -

-

- Vacuum -

- Vacuum -

-

- Sealing -

- Sealing -

-

- Gas Flush -

- Gas Flush -

| x | x | x | x |

MAP Packaging

Extend the shelf life of the product and guarantee longer conservation for the final consumer.

Ultra hygienic design

Both in terms of available options and construction, ILPRA’s in-line FS models guarantee the integrity of the packaged product, maximum accessibility and cleanliness of every component of the machine

Totally customisable

Total Brushless

This line allows you to optimise the timing of each work step by increasing productivity and improving product and container handling.

STATIONS

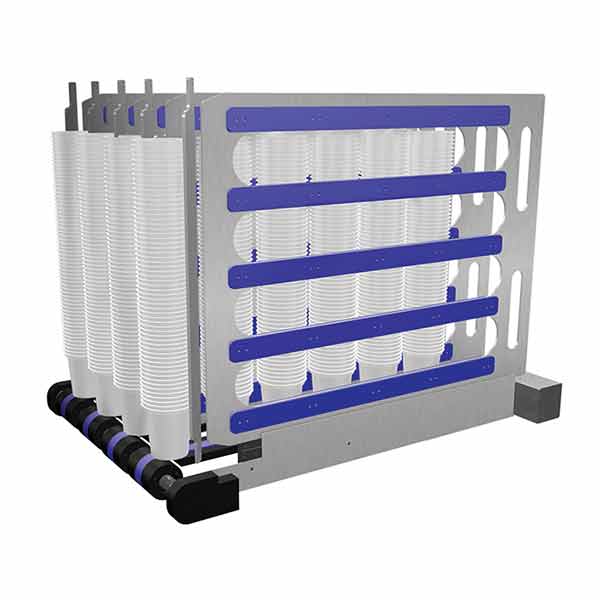

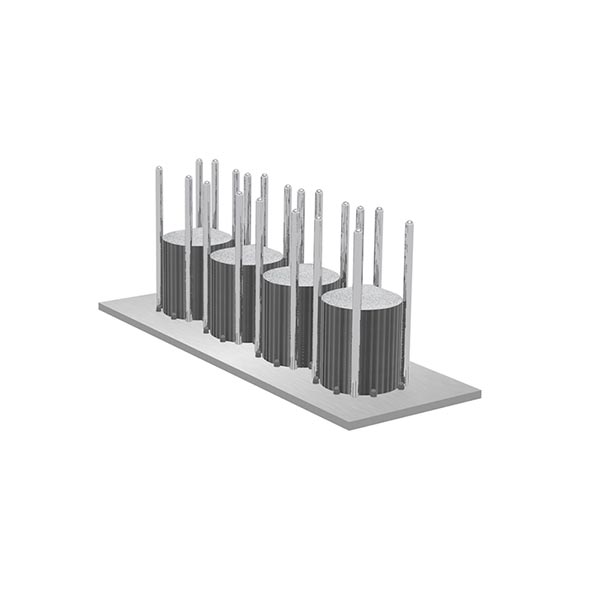

| HIGH CAPACITY STORAGE Thanks to the automatic infeed conveyor and the large capacity storage, this station guarantees the maximum autonomy of both machine and operators |

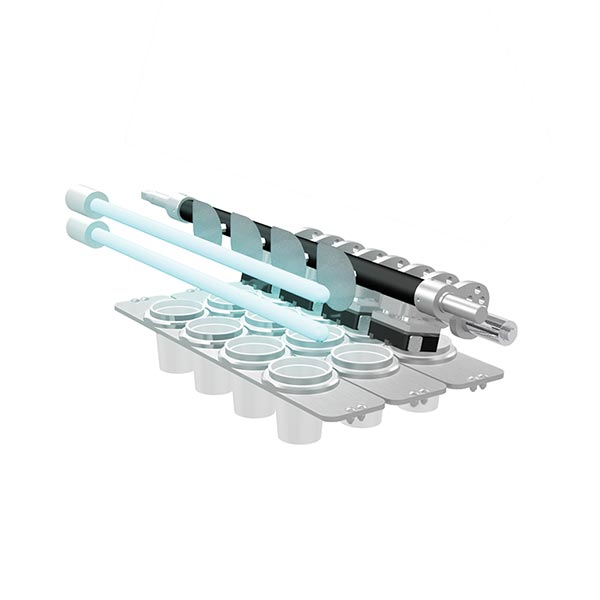

| CUPS SANIFICATION Realised by UVC lamps and/or pulsed light, or by hydrogen peroxide atomisation. |

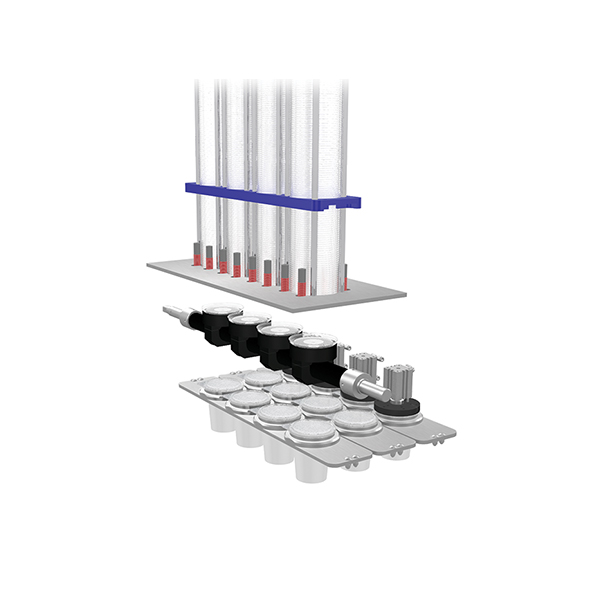

| DOSING SYSTEM It forms the heart of the entire machine and is designed according to the specific needs of the customer and the type of product to be packaged. |

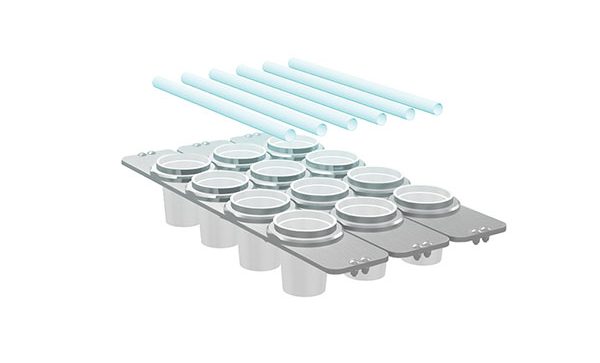

| LIDS DENESTER The storage for pre-cut lids ensures the correct positioning on the pot. Designed to guarantee the maximum autonomy. |

| PRECUT LIDS SANIFICATION Lids sanification station using UVC or pulsed light lamps, ensuring the reduction of any bacterial load on the pre-cut lids. |

| SEALING STATION Lid or film sealing of the pots. The high efficiency of this station guarantees an extended product shelf-life. |

| LIDS STORAGE This station allows a lid to be placed on the container. The high capacity of the storage guarantees a high autonomy of operation. |

| CUPS EJECTION Ordered and regular exit of pots on a fully washable belt. Many accessories and secondary packaging systems can be installed after this station. |

| TRAY-CARRIER CLEANING AND DRYING Automatic washing system for cleaning and drying tray-carriers. |