- Rotative

Fill Seal 2500

Our compact and flexible Fill Seal model is designed to be user-friendly. It can work with various cup materials. The rotary table and machine structure enable a wide range of tailor-made solutions for packaging different types of food products, such as liquids, creams, pastes, grains, and solid food. This machine can handle one cup per station with an output of around 2,500 pieces per hour.

-

- MAP/ATP -

- MAP/ATP -

-

- Vacuum -

- Vacuum -

-

- Sealing -

- Sealing -

-

- Gas Flush -

- Gas Flush -

| Technical data | Fill Seal 2500 | Fill Seal 2500 Large | Fill Seal 2500 XL |

| Dimensions | 209 x 115 x h 196 cm | 240 x 127 x h 195 cm | 189 ( Lid ) / 205 (Film) x 207 x h 232 cm |

| Weight | approx. 600 Kg | approx 900 Kg | approx. 1050 Kg |

| Electric power lid | 3 Kw | 3,5 kW | 5,5 kW |

| Electric power film | 3 kW | 3,5 (N) - 4.5 (VG) kW | 5 (N) - 6 (VG) kW |

| Pots per cycle | 1 | 1 | 1 |

| Ø Max Cups Lid | 125 mm | 150 mm | 200 mm |

| Ø Max Cups Film | - | 150 mm (N) - 125 mm ( VG) | 200 mm (N) - 180 mm ( VG) |

| Max height cup | 130 mm | 130 mm | 180 mm |

Touch Screen Panel

The touch screen control panel allows for easy settings of all parameters and stores multiple recipes for quick access by the operator.

Modified Atmosphere Packaging

ILPRA offers modified atmosphere packaging on this model, a nearly exclusive feature for a rotary table filling and sealing machine.

Available dosers

FS 2500 can be equipped with various dosing options, including volumetric, timed, timed with weight control, and drawer doser. Additionally, the machine can be equipped with a multi-head system for specific requirements.

Completely washable

ACCESSORIES

| ULTRA CLEANING SYSTEM Each of our models can be equipped with sanitization systems such as UVC lamps, pulsed light and hydrogen peroxide. |

| LAMINAR FLOW HOOD The constant flow of micro-filtered air inside the machine helps to increase the shelf life of your product. |

| CRIMPING SYSTEM The crimping system is installed on the exit belt of glass or ceramic pot fillers. This allows the lid to be crimped to the side edge of the pot. |

| PICK & PLACE Device that allows the automatic placing of pre-filled containers inside the machine.

|

| INKJET Inkjet printer that allows to complete your packaging with additional information such as: expiration date, production lot, etc. |

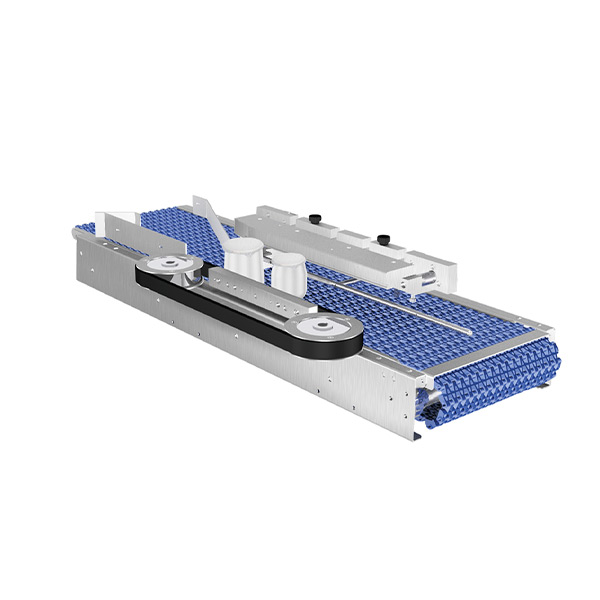

| HIGH CAPACITY STORAGE Thanks to the automatic infeed conveyor and the large capacity storage, this station guarantees the maximum autonomy of both machine and operators. |

| DOSING SYSTEMS Volumetric, timed, drawer, flowmeter: ILPRA has every type of doser to make your filling fast and accurate. |

| SUCTION OF FOREIGN MATERIALS An air jet placed a few millimeters from the bottom of the container lifts any foreign bodies which are sucked up and removed. |

| CIP CLEAN-IN-PLACE SYSTEM Independent system for washing the dosing unit in complete autonomy. |