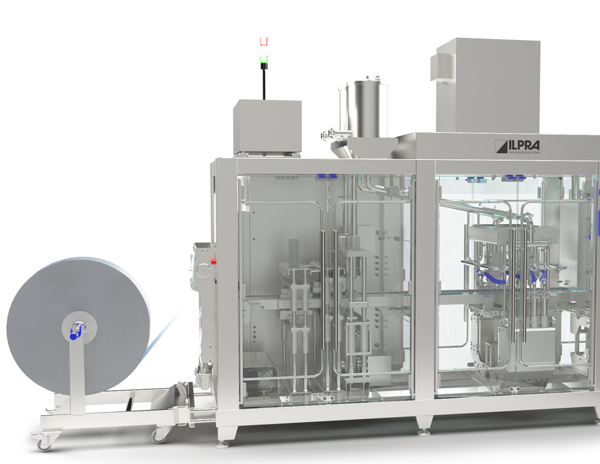

- In Line

Form Fill Seal MD

The MD models of ILPRA’s Form Fill Seal line are driven by the following principles:

Utilization of servo-assisted electrical movements as the technological foundation

Integration of standardized components from top-notch manufacturers in the market

Implementation of advanced software for easy and efficient management of machine functions, establishing close connection with customer’s computer systems (CPS 4.0 cyber-physical system)

User-friendly and comprehensive HMI (Human-Machine Interface)

Streamlined and effective solutions to speed up and simplify packaging operations

Compact design

Our work aims to deliver a machine that ensures utmost production efficiency, precise and hygienic dosing, minimized operating costs through streamlined maintenance procedures, and silent operation. The ergonomic and functional design facilitates user-friendliness, maintenance, sanitization, and provides high customization options through various optional extras.

Our branches in the Middle East area highly recommend our diverse range of dairy, yoghurt and sauces products. These models have been selling incredibly well and cater to unique preferences.

| Technical data | Form Fill Seal | ||

| Production capacity | 25 cycles/min max | ||

| Forming film | 460 mm. max | ||

| Max. Step | 260 mm | ||

| Max height package | 100 mm |

Ultra Hygienic Design

ILPRA’s FFS models ensure the integrity, accessibility, and cleanliness of every component of the machine, providing maximum options and impeccable construction for the packaged product.

Highly customisable

Highly customizable format, cutting options, required level of hygiene, sanitation, output, and countless other options are available.

Highly integrable

Total Brushless

Optimize the timing of each work step, increase productivity, and enhance product and container handling with this line.