- Rotative

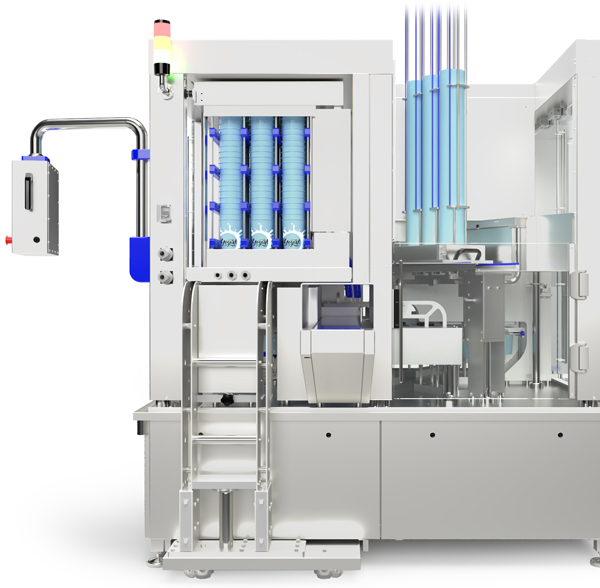

Fill Seal R12 e S12

The Fill Seal R12 is an advanced filling machine equipped with a rotary table and servo-controlled work stations. This innovative design optimizes each work phase, resulting in heightened productivity and better management of product and container flow. For those seeking a simpler option, ILPRA also provides the S12 model which offers a streamlined solution with limited customization capabilities.

-

- MAP/ATP -

- MAP/ATP -

-

- Vacuum -

- Vacuum -

-

- Sealing -

- Sealing -

-

- Gas Flush -

- Gas Flush -

| Technical data | Fill Seal R12 | Fill Seal S12 | |

| Dimensions | 215x 219x h 230 cm | 240 x 223 x h 232 cm | |

| Weight | circa 2900 Kg | circa 2900 Kg | |

| Electric Power Lid | 11 Kw | 10,5 kW | |

| Electric Power Film | 13 (N) - 16 (VG) kW | - | |

| Pots per cycle | up to 6 | up to 6 | |

| Ø Max Cups Lid | 160 mm | 160 mm | |

| Ø Max Cups Film | 160 mm | - | |

| Max height Cup | 170 mm | 170 mm |

Total Brushless

With the FS R12, you can maximize work step timing for enhanced productivity and superior handling of products and containers.

MAP Packaging

ILPRA offers a distinctive feature for its rotary table filler and sealer by providing protective atmosphere packaging, making it stand out from the rest.

High capacity storage

With its automated container feeding and expansive storage capacity, this station ensures optimal autonomy for both machines and operators.

Simplified mould change

With our advanced system, you have the power to effortlessly adjust impression quantities, effectively reducing machine downtime to a minimum.

ACCESSORIES

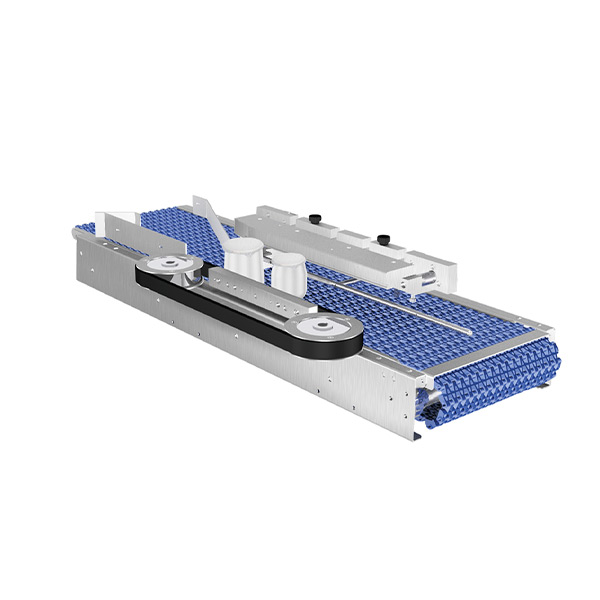

| HIGH CAPACITY STORAGE Thanks to the automatic infeed conveyor and the large capacity storage, this station guarantees the maximum autonomy of both machine and operators |

| PICK & PLACE Device that allows the automatic placing of pre-filled containers inside the machine. |

| SUCTION OF FOREIGN MATERIALS An air jet placed a few millimeters from the bottom of the container lifts any foreign bodies which are sucked up and removed. |

| ULTRA CLEANING SYSTEM Each of our models can be equipped with sanitization systems such as UVC lamps, pulsed light and hydrogen peroxide. |

| DOSING SYSTEMS Volumetric, timed, drawer, flowmeter: ILPRA has every type of doser to make your filling fast and accurate. |

| LAMINAR FLOW HOOD The constant flow of micro-filtered air inside the machine helps to increase the shelf life of your product. |

| CRIMPING SYSTEM The crimping system is installed on the exit belt of glass or ceramic pot fillers. This allows the lid to be crimped to the side edge of the pot. |

| INKJET Inkjet printer that allows to complete your packaging with additional information such as: expiration date, production lot, etc. |

| CIP CLEAN-IN-PLACE SYSTEM Independent system for washing the dosing unit in complete autonomy. |